40 to 50% Nickel-Iron Alloys

Cost Optimized Solutions for Demanding Magnetic Sensor Applications

This group of nickel-iron alloys is a good choice when it comes to detecting high currents or guiding the magnetic flux of hard magnets (e.g. in a torque sensor). This class of materials is characterized by saturation inductions of about 1.3 T to 1.5 T, a coercivity between 3.5 A/m and 10 A/m as well as high permeability. By selecting appropriate rolling and annealing conditions, the shape of the magnetization curve can be varied over a wide range.

Benefits:

-

Low coercivity

-

High saturation polarization

-

Lowest specific iron-losses

PERMENORM® 5000 H2 - typical thickness of 0.1 to 0.35 mm

- Toroidal cores and core laminations, e.g. in current transformers and in residual current devices (RCDs)

- Storage chokes

- Laminated stacks

- Shieldings

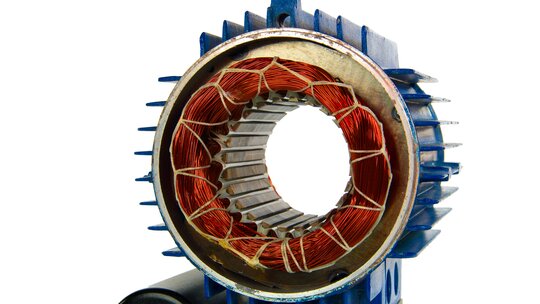

PERMENORM® 5000 V5 - isotropic microstructure

- Rotor and stator laminations

- Relay parts

- Sensors

- Flux guiding parts

MEGAPERM® 40L

- Stacked laminations in high speed motors

- Flux guiding parts

- Parts for sensors, relay and system parts, transformers and chokes

- Sensitive sensor applications

- Low loss motors, especially for high frequencies

PERMENORM 5000 H2 and PERMENORM 5000 V5 both have the same composition with a saturation polarization of JS = 1.55 T. These technically important materials, with round shape of the hysteresis loop and small coercivity, have either a scondary-recrystallized or an isotropic microstructure developed by primary recrystallization. The permeability steadily increases with higher final annealing temperature and correspondingly larger grain size.

PERMENORM 5000 V5, with an isotropic structure (rotor grade), offers a low coercivity of HC ≈ 4 A/m. The maximum DC permeability is well above µmax > 100,000.

MEGAPERM 40L has a Ni-content of 40 wt% and combines high saturation of JS = 1.48 T with increased electrical resistivity of ρ = 0.6 µΩm.

ULTRAVAC 44 V6 is a 44%Ni3%Mo non-oriented NiFe-alloy with higher saturation polarization than MUMETALL. The highest electrical resistivity (ρ = 0.8 µΩm) for this type of alloys leads to lowest magnetization losses.

PERMENORM® 5000 H2 - typical thickness of 0.1 to 0.35 mm

- Toroidal cores and core laminations, e.g. in current transformers and in residual current devices (RCDs)

- Storage chokes

- Laminated stacks

- Shieldings

PERMENORM® 5000 V5 - isotropic microstructure

- Rotor and stator laminations

- Relay parts

- Sensors

- Flux guiding parts

MEGAPERM® 40L

- Stacked laminations in high speed motors

- Flux guiding parts

- Parts for sensors, relay and system parts, transformers and chokes

- Sensitive sensor applications

- Low loss motors, especially for high frequencies

PERMENORM 5000 H2 and PERMENORM 5000 V5 both have the same composition with a saturation polarization of JS = 1.55 T. These technically important materials, with round shape of the hysteresis loop and small coercivity, have either a scondary-recrystallized or an isotropic microstructure developed by primary recrystallization. The permeability steadily increases with higher final annealing temperature and correspondingly larger grain size.

PERMENORM 5000 V5, with an isotropic structure (rotor grade), offers a low coercivity of HC ≈ 4 A/m. The maximum DC permeability is well above µmax > 100,000.

MEGAPERM 40L has a Ni-content of 40 wt% and combines high saturation of JS = 1.48 T with increased electrical resistivity of ρ = 0.6 µΩm.

ULTRAVAC 44 V6 is a 44%Ni3%Mo non-oriented NiFe-alloy with higher saturation polarization than MUMETALL. The highest electrical resistivity (ρ = 0.8 µΩm) for this type of alloys leads to lowest magnetization losses.

| Alloy | Mass Density ρ [g / cm3] |

Electrical Resistivity ρel [μΩm] |

Curie Temperature TC [°C] |

Thermal Conductivity λ [W/mK] |

|---|---|---|---|---|

| Permenorm 5000 H2 | 8.25 | 0.45 | 440 | 13 - 14 |

| Permenorm 5000 V5 | 8.25 | 0.45 | 440 | 13 - 14 |

| MEGAPERM 40L | 8.2 | 0.6 | 310 | 13 - 14 |

| ULTRAVAC 44 V6 | 8.25 | 0.8 | 300 | 13 - 14 |

| Alloy | Mass Density ρ [g / cm3] |

Electrical Resistivity ρel [μΩm] |

Curie Temperature TC [°C] |

Thermal Conductivity λ [W/mK] |

|---|---|---|---|---|

| Permenorm 5000 H2 | 8.25 | 0.45 | 440 | 13 - 14 |

| Permenorm 5000 V5 | 8.25 | 0.45 | 440 | 13 - 14 |

| MEGAPERM 40L | 8.2 | 0.6 | 310 | 13 - 14 |

| ULTRAVAC 44 V6 | 8.25 | 0.8 | 300 | 13 - 14 |

Downloads

Related Products

69 % to 82 % Nickel-Iron

These high permeability materials differ mainly in the level of permeability. Permeability increases in the series from the standard grade MUMETALL to the highest grade ULTRAPERM 250. VACOPERM 100 D is a solid material.

Soft Magnetic Stamped Parts

All crystalline alloys can be processed further to stamped parts. VAC has state-of-the-art facilities for punching, deep-drawing and further processing methods like interlocking or wire-EDM.

Components for Electric Motors

Whether you are looking for materials, permanent magnets or complete stator and rotor assemblies, we provide a comprehensive range of solutions for electric drives.

Contact Us Think Global - Act Local

We are looking forward to support you.